BonPEC is an innovative Pulsed Eddy Current (PEC) technology that offers an advanced approach to corrosion detection, measurement, and monitoring in low-alloy steel pipelines and vessels. This lightweight and adaptable system includes two standard probes and three handheld display options, along with specialized software for advanced PECT data analysis and detailed reporting functions. Applications range from in-service corrosion monitoring, splash zone inspection, and wall thickness monitoring to inspection through repair wraps and assessment of remaining ligaments for corrosion. Pulsed Eddy Current technology enables accurate measurements without direct contact, special cleaning, or specific surface preparation, resulting in significant cost savings for the customer by eliminating the need to remove expensive and unnecessary insulation. This effective and cost-effective system is used in onshore and offshore industries, as well as in the energy sector, for the inspection of insulated and corroded components and parts.

State-of-the-art Pulsed Eddy Current Technology.

Two probes as standard within the kit.

Three portable screen display options.

Lightweight adaptable system.

NDT Inspection workflow based software delivering advanced PECT data analysis and evaluation.

Advanced reporting features.

Applications include: In-Service Corrosion Monitoring, Splash Zone Inspection, Wall Thickness Monitoring and Inspection through Repair Wraps, Remaining Ligament Assessment through Corrosion.

BonPEC is an innovative Pulsed Eddy Current (PEC) technology that offers an advanced approach to corrosion detection, measurement, and monitoring in low-alloy steel pipelines and vessels. This lightweight and adaptable system includes two standard probes and three handheld display options, along with specialized software for advanced PECT data analysis and detailed reporting functions. Applications range from in-service corrosion monitoring, splash zone inspection, and wall thickness monitoring to inspection through repair wraps and assessment of remaining ligaments for corrosion. Pulsed Eddy Current technology enables accurate measurements without direct contact, special cleaning, or specific surface preparation, resulting in significant cost savings for the customer by eliminating the need to remove expensive and unnecessary insulation. This effective and cost-effective system is used in onshore and offshore industries, as well as in the energy sector, for the inspection of insulated and corroded components and parts.

It is a non-intrusive electromagnetic technique based on Pulsed Eddy Current which allows detection, measurement and monitoring of corrosion in low alloyed carbon steel pipes and vessels through their insulations, coatings, paints, concrete fireproofing or marine growth. The technology does not require direct contact, cleaning or special and specific preparation of the surface of the object to be examined, therefore no costly and unnecessary insulation removal is required to perform the PEC examination with a considerable cost saving for the client.

PEC is the efficient and cost effective solution for the examination of insulated and corroded components and parts in the on- and offshore industry and in the energy sector.

Corrosion Under Insulation (CUI), Corrosion Under Fireproofing (CUF) and Flow Accelerated Corrosion (FAC) as well as Well Integrity are typical PEC successful applications, solutions and benefits. PEC performance is effective also for semi-contact measurements carried out with dirty, rough, cold and high temperature objects. In general PECT can perform thickness assessment on Carbon Steel where there is a stand off that means ultrasonic thickness measurement is not applicable.

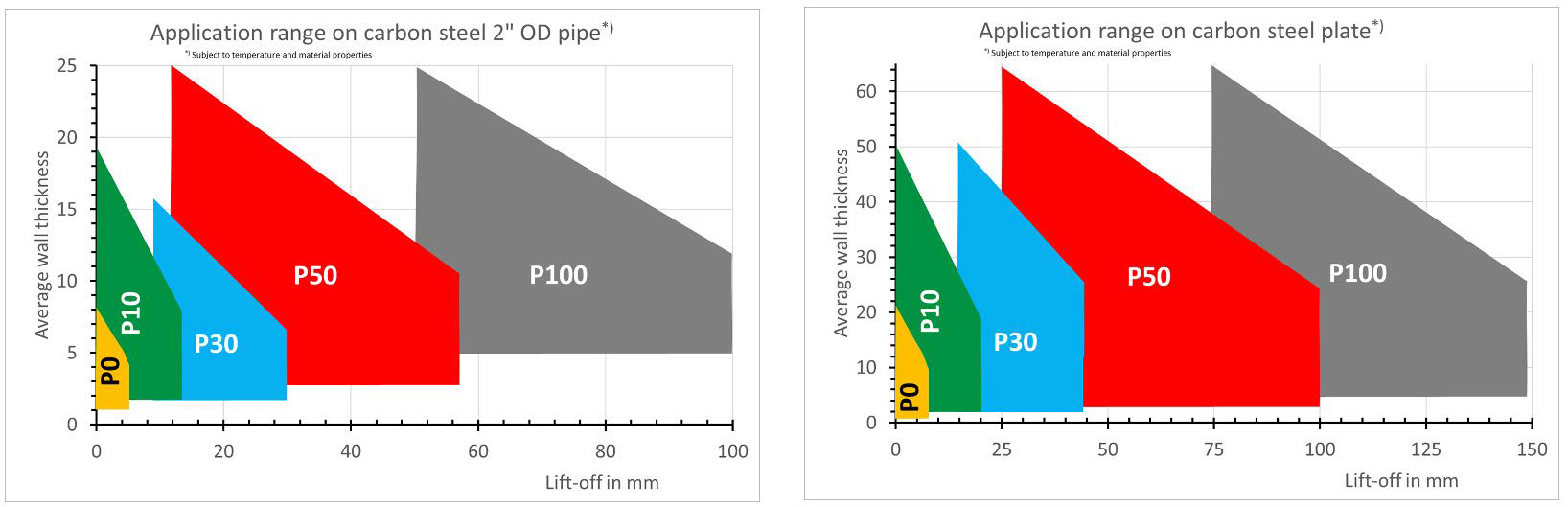

Depending on the lift-off and the average wall thickness of the object being inspected, there is a range of probes to choose from in order to optimize the reliability of the results. For a large lift-off a large probe is needed. Two probes are available as standard, P0.5 and P1.0, with other options available.

Depending on the lift-off and the average wall thickness of the object being inspected, there is a range of probes to choose from in order to optimize the reliability of the results. For a large lift-off a large probe is needed. Two probes are available as standard, P0.5 and P1.0, with other options available.

The applicable range of each probe depends on the material properties and measurement geometry of the target, but most importantly the lift-off and average wall thickness

The above diagrams show both a probe selection criteria for a carbon steel flat plate and a 2” outer diameter carbon steel pipe, based on avergae wall thickness and lift-off.

BonPEC probes are designed to minimize false readings, hence they are insensitive to metal objects near the probe, except for the object that is right below it. Due to magnetic field focusing, the probes are (within boundaries) insensitive to lift-off change, angle mis-match or variations of sheeting thickness. These properties are all important for field measurements, reducing false calls and increasing effectiveness of data interpretation.

BonPEC software has been developed based on the way a typical NDT survey is performed. Initially one needs to know what needs to be investigated, which is represented by client and object parameters.

Important parameters are the type of object (pipe, plate or bend), the nominal wall thickness, the lift-off and the of cladding used etc. Based on this information and the experience of the operator, a suitable probe is selected and a suitable scan is defined. The BonPEC program gives tools to inspect, check, evaluate and report the measurement data.

Software features

Fast data collection

Direct real-time interpretation and results;

Digitally stored data.

User-friendly operation (touchscreen)

Advanced PEC signal presentation feature.

Advanced PEC data analysis and evaluation algorithms (footprint minimum WT value etc.)

Advanced reporting features (Auto report generation, Graphs, 3D result projection on object model/photo etc.)

In-service corrosion monitoring.

Interface language user dependent.

Operator level dependent software and training.

State-of-the-art Pulsed Eddy Current Technology.

Two probes as standard within the kit.

Three portable screen display options.

Lightweight adaptable system.

NDT Inspection workflow based software delivering advanced PECT data analysis and evaluation.

Advanced reporting features.

Applications include: In-Service Corrosion Monitoring, Splash Zone Inspection, Wall Thickness Monitoring and Inspection through Repair Wraps, Remaining Ligament Assessment through Corrosion.

Non-Intrusive Inspection (NII).

No direct surface contact.

No surface cleaning or preparation required.

No removal of sheeting or thermal insulation.

Measures through marine growth, coatings and concrete.

Technology is effective above and underwater.

Carbon steel (ferromagnetic)

WT 3-65 mm

Insulation thickness <200 mm (probes pending)

Aluminium or Stainless Steel sheeting

Temp. -150°C to 500 °C

Min. pipe diameter 50mm (2”)

Accuracy 5 %

Down to 50% AWT reduction to the reference AWT

+/- 50% Lift-Off variation to the reference Lift-Off

Repeatability 2%

| Portable Screen Display Options |  |

|

|

| 10.1” Rugged Tablet PC | 11.6” Rugged Tablet PC | Rugged Notebook 14” | |

| Battery Life | 8 hours | 10 hours | Up to 30 hrs |

| Battery | Integrated Battery: 7.6V, 8000mAh | Hot Swap Battery: 7.6V, 4800mAh | Hot Swap Battery: 10.8V, 6900mAh |

| Touchscreen Display | 10.1” (256 mm) | 11.6” | 14” |

| Weight | 1.15kg | 1.39kg | 2.38kg |

| 3kg inc. BonPEC & Stand | 2.8kg inc.BonPEC & Stand | 3.28kg inc. BonPEC | |

| Size | 186 x 70 x 26.5mm | 317 x 215 x 23.8mm | 350 x 293 x 38.5mm |

| 7.3” x 2.75” x 1” | 12.4” x 8.46” x 0.9” | 13.7” x 11.5” x 1.5” | |

| Tablet/Notebook IP rating | IP67 | IP66 | IP53 |

| MIL SPEC | MIL-STD_810G | MIL-STD_810H MIL-STD_416G | MIL-STD_810H |

| Kit Part Number | KIPEC001 | KIPEC002 | KIPEC003 |

subscribe to receive promotions and offers, and download the content

You have successfully subscribed to the newsletter

There was an error while trying to send your request. Please try again.

Thanks for your download!

SAVE CLOSE THIS MESSAGE AND CLICK THE PDF YOU WANT TO DOWNLOAD, WE ARE HAPPY TO BE ABLE TO OFFER WHAT YOU WERE LOOKING FOR