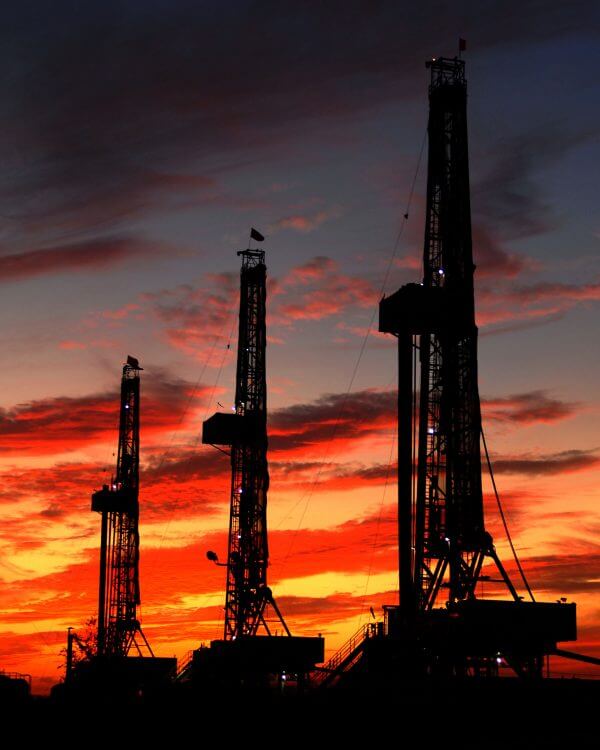

El sector de petróleo se encarga de la exploración, extracción, refinación y transporte del petróleo. La industria petrolera es vital para muchas industrias y mantener el sector industrial tal y como esta establecido hoy en día. Debido a las condiciones que se requieren para los diversos procesos industriales la exigencia que se le da a los materiales es muy alta. La rigurosidad en los procesos inspección son de los mas altos estándares y por lo tanto los equipos de ensayos no destructivos a implementar a su vez deben ser los mejores.

La corrosión es uno de los grandes problemas de la industria petrolera. La correcta inspección asegura la confiabilidad de los procesos y el estudio adecuado de la vida remanente de los sistemas.

La inspección mediante mapeo de corrosión se ha convertido en una de las técnicas principales en los procedimientos de inspección debido a su facilidad de uso, optimización del proceso y confiabilidad de los resultados.

El aislamiento en la industria petrolera muchas veces es una necesidad para ciertas aplicaciones. El problema que acarrea la presencia del aislante es que si la humedad penetra en combinación con las altas temperaturas se genera corrosión.

Por lo tanto la inspección de la tubería es muy importante y métodos convencionales de inspección de tubería como ultrasonido son una opción pero generan una gran inversión debido a que hay que remover el aislante para hacer la inspección y luego volverlo a colocar. Existe una solución mucho mas eficiente en la que no se debe remover el aislante, esta técnica es la técnica de corrientes inducidas de pulso (Pulsed Eddy Current).

Solución:

Los tanques de almacenamiento son componentes fijos que se encuentran en plantas petroleras. Estos componentes deben ser inspeccionados con los equipos que ofrezcan la mayor eficiencia debido a que el tiempo que se debe invertir en los tanques es elevado debido a las dimensiones que se manejan.

Existen dos zonas criticas que deben ser inspeccionadas. En primer lugar el piso del tanque que se recomienda hacer una inspección mediante un sistema de MFL para localizar las zonas corroídas y luego una inspección detallada de dicha zona con un sistema de ultrasonido.

La segunda zona critica que debe ser inspeccionada son las paredes del tanque. Para esto se recomienda la inspección mediante un sistema ultrasónico que pueda generar barridos, por lo tanto el equipo a utilizar seria uno con sistema de ruedas magnéticas que se pueda desplazar por la paredes además de la facilidad a la hora de la inspección evitando tener que armar cuerpos de andamios alrededor de los tanques.