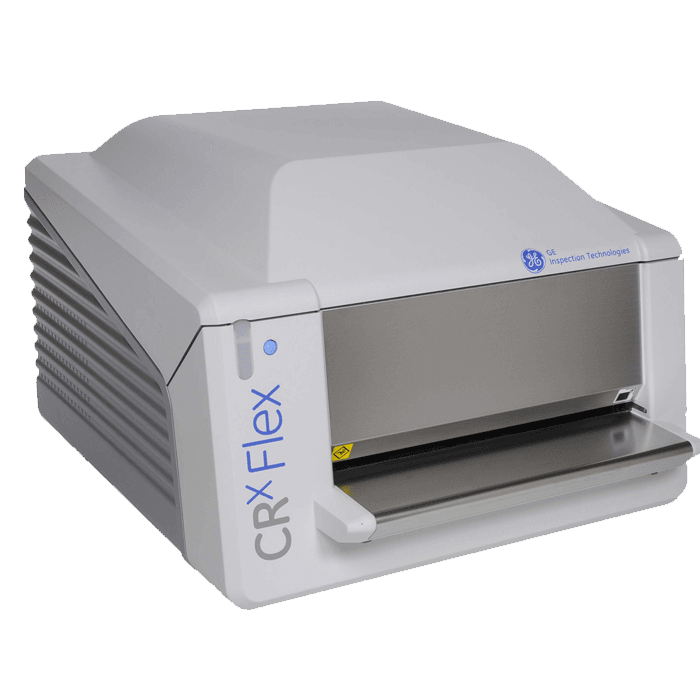

The CRxFlex™ is a multipurpose workhorse for a wide range of applications. Designed specifically for nondestructive testing (NDT), it delivers better efficiency, performance, throughput, and image quality than any other system in today’s NDT market—at lower doses for both isotopes and X-ray sources.

Due to high read-out efficiency, this field-proven scanner boasts shorter exposure times, excellent image quality, improved signal to noise ratio (SNR), and basic spatial resolution (SRb). It increases reliability and productivity.

Upgraded core technology offers a variety of scan resolutions from 25 micron to 200 micron, covering all possible NDT segments.

This results in extreme high throughput for oil and gas applications like CUI, ISI and erosion/corrosion inspections, while also providing the highest image quality, which covers even the most stringent weld standards.

Like all available GE CR scanners, the CRxFlex solution is DICONDE-compliant for image acquisition, analysis and data management.

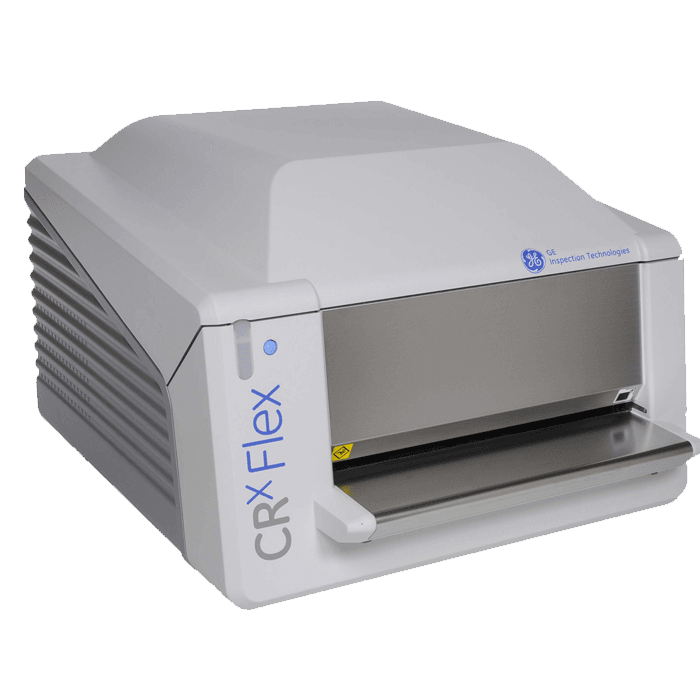

The CRxFlex™ is a multipurpose workhorse for a wide range of applications. Designed specifically for nondestructive testing (NDT), it delivers better efficiency, performance, throughput, and image quality than any other system in today’s NDT market—at lower doses for both isotopes and X-ray sources.

Due to high read-out efficiency, this field-proven scanner boasts shorter exposure times, excellent image quality, improved signal to noise ratio (SNR), and basic spatial resolution (SRb). It increases reliability and productivity.

Upgraded core technology offers a variety of scan resolutions from 25 micron to 200 micron, covering all possible NDT segments.

This results in extreme high throughput for oil and gas applications like CUI, ISI and erosion/corrosion inspections, while also providing the highest image quality, which covers even the most stringent weld standards.

Like all available GE CR scanners, the CRxFlex solution is DICONDE-compliant for image acquisition, analysis and data management.

Peace of mind: Built for the long haul, our durable, modular design allows for faster, easier service with minimal damage or wear

Higher throughput: Multiple imaging plates can be scanned simultaneously with the ability to handle any shape or size—meaning fewer overall exposures and retakes

subscribe to receive promotions and offers, and download the content

You have successfully subscribed to the newsletter

There was an error while trying to send your request. Please try again.

Thanks for your download!

SAVE CLOSE THIS MESSAGE AND CLICK THE PDF YOU WANT TO DOWNLOAD, WE ARE HAPPY TO BE ABLE TO OFFER WHAT YOU WERE LOOKING FOR